TeraPower Technology Inc. was first established in September 2008 as a joint venture between Powertech Technology Inc. in Taiwan andTera Probe, in Japan, as a subsidiary of Tera Probe, and became an official member of the Powertech Technology Group (PTI Group) in 2017. The primary services include wafer testing services for memory, and logic products, and final testing for logic products. We are also a professional service provider of semiconductor testing services worldwide.

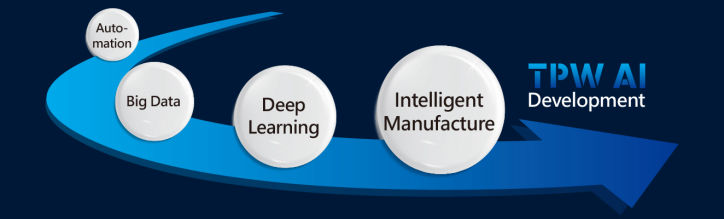

Headquarters located in Hsinchu Industrial Park, close to our customers and suppliers. We adhere to the business policy of recognizing talented staff members, promoting teamwork, and pursuing advanced technology. The quality of our test services are efficiency are upgraded through Artificial Intelligence-assisted and highly automated testing technology. Furthermore, our various resources can maximize our test output, so we have a competitive advantage over peers.

TeraPower Technology Inc. was established as a joint venture between Powertech Technology Inc. in Taiwan and Tera Probe in Japan to provide advanced memory wafer testing services.

Our first facility (space with 23,801 square meters) was acquired for the rapid growth in production demand.

Established WT business unit for logic products to provide diversified testing services for testing services.

Obtained TS16949 certification and created wafer testing environment for automotive products. We are driven to become a global wafer testing company for automotive.

Established FT business unit for logic products to provide comprehensive testing services to enhance competitiveness and growth opportunities.

Became a service provider for a major international automotive chip manufacturer. Certified by several leading customers, and started mass production of wafer testing services for automotive devices.

Acquired by the Powertech Technology Inc. Group. Integrated group strategy and advantages to provide diversified products and full turnkey services.

The second plant was built and start operation in order to meet growth demand.

With the success of automotive WT services, we also received FT orders from an international auto chip manufacturer.

Successfully developed operation-related Artificial Intelligence technologies to improve production efficiency and test quality.

In response to the needs of the automotive and AI markets, the third factory will be opened in 2025.

.